Beckermus Technologies: Solving your Chip Packaging Challenges

The interfaces of the chips crucial for the reliability of the systems. Beckermus Technologies provides holistic chip packaging solutions to the chip world Chips are the heart of a system, but without an interface to the outside world, they will not be functional. Beckermus Technologies can offer you a huge variety of chip

packaging solutions for the challenges of MEMS, microelectronic, photonics IC, IoT and more.

The semiconductor industry is getting its push from market needs that are translated into engineering requirements. The chip itself is indeed the heart of the system, but without an interface to the outside world, it cannot be functional. As in our bodies where organs are connected to each other, the chip has its multidisciplinary interfaces (mechanical, electric, optical, electromagnetic, acoustic, thermal and more) between itself and the rest of the electronic system. These interfaces are crucial for the reliability of the system.

Reliability of the system first

When considering how a chip interacts with the outside world, many different requirements must be taken into account, and this is why working on the chip packaging should be holistic. Our company has extensive experience in providing holistic chip packaging solutions to the chip world, including the civilian and military market. It is very important that we provide the required reliability of the electronic system by choosing the right methods and processes for chip packaging. Reliability is determined by the combination of the all components and interfaces between them. Moreover, if we look inside the components themselves, we will find that each electronic component is also composed of sub-parts and interfaces. Ultimately, in the analysis of many failures from history, we can find that a lot of the failures in electronic systems are caused by the design, production or poor functioning of one interface or another. Therefore, a lot of attention should be paid to the interfaces.

High performance at low cost

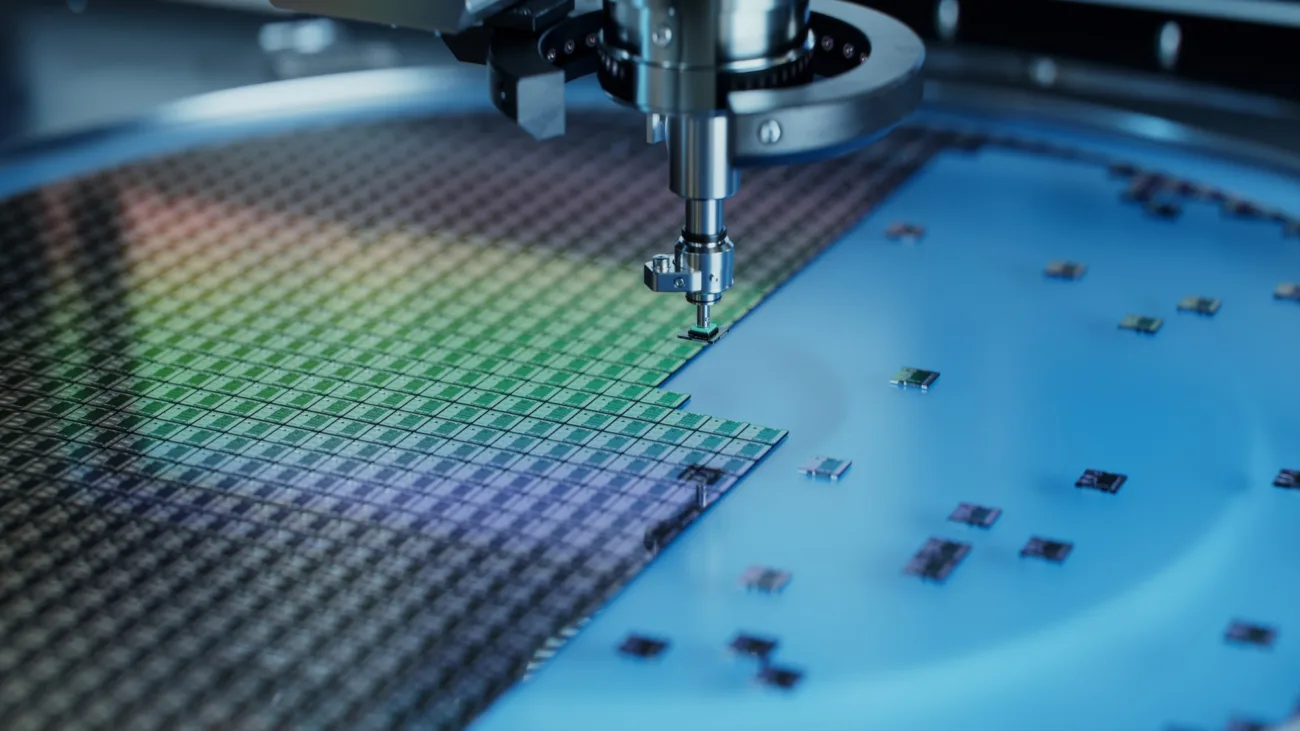

The packaging means the set of processes and materials by which the parts of the electronic system are assembled. The parts can be bare dies, packages, PCBs, light sources (LEDs, VXCELs), optic fibers, lenses and other components or devices. All parts can be made from various raw materials. In the list of processes of chip packaging, you can find terms like wire bonding, flip

chip, inert soldering, conductive and non-conductive adhesive, welding, ultrasonic connection processes, and more. All these processes can be hand-made

or fully automated in our facilities. For several years, there has been a slowdown in Moors Law. In such an era, it is necessary to find other technologies that will enable the reduction of component dimensions while maintaining low cost and high performance. The chip packaging technologies we are specialized in enable small dimensions, high performance and competitive price to enable the chip to penetrate the market. We will be happy to understand your company’s needs and adapt the solutions appropriate for the system enclosure.

End-to-End Services for your Chip Packaging Challenges

Beckermus Technologies specializes in advanced assembly and integration solutions within the fields of microelectronics and optoelectronic packaging. Established in 1998, our company is driven by a passion for innovation and the relentless pursuit of technological advancement. We excel in assembly across various sectors and applications, including medical devices, communications, automotive, AR/VR, defense, aerospace, and more. Our expertise spans from design to prototyping and full turnkey solutions for serial production. With a customer-oriented approach, we provide tailored solutions to meet the unique needs and challenges of our global clients. Our production takes place in our 8000-square-foot cleanroom facility, where we adhere to ISO 13485 for medical devices, AS9100D for aerospace, as well as IPC-A-610 and MIL-STD 883 standards.

Our experienced team is dedicated to excellence, continually developing innovative assembly methods and services to enhance efficiency, productivity, and overall success.

For further details please contact us at info@beckermus.com

This content might interest you as well

More Categories

Related Posts

Bridging Innovation: How Israel and India Can Accelerate the Semiconductor Revolution India’s ambition to become a global semiconductor hub can

One-on-one Interview with Eyal Waldman: Israel has huge advantages in Semiconductors Eyal Waldman, CEO and one of the founders of

vSync Circuits Ltd., founded in 2010 by industry veterans Dr. Reuven Dobkin, Leonid Brook, and Prof. Ran Ginosar, develops innovative

COMPLETE DICING SOLUTIONS ADT (Advanced Dicing Technologies) is a world leading provider of comprehensive solutions for complexed dicing applications. With